There is this one process used to create various products like countertops, tiles, and monuments. It requires special skills, tools, and equipment. This ensures that stone materials are prepared for different purposes, adding beauty and functionality to various spaces – so learn more about it below.

Understanding Stone Fabrication

First of all, stone fabrication begins with selecting the right type of stone. Stones like granite, marble, limestone, and quartz are commonly used. The choice depends on the project, design, and customer preference. Each stone has unique properties, like hardness, color, and texture.

Once the stone is selected, it is transported to a fabrication facility. Here, skilled fabricators use specialized tools to shape the stone according to the desired design.

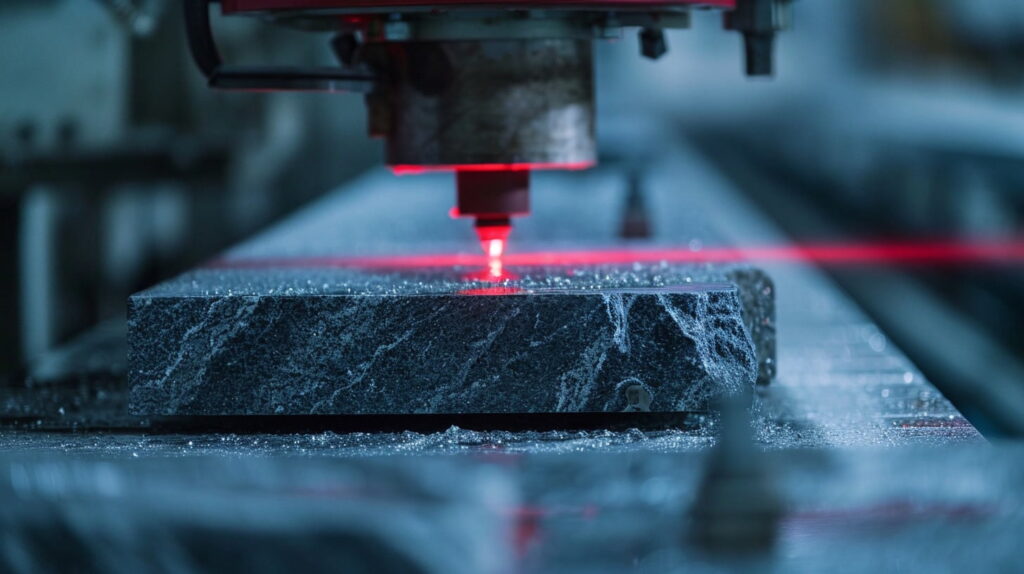

The Cutting Process

First, large stone slabs are cut down using tools like bridge saws or water jet cutters. These machines use high-pressure water jets or diamond blades to make precise cuts. The cutting process ensures that the stone pieces match the required dimensions for the project.

Shaping the Stone

After cutting, the next step is shaping the stone. This involves refining the edges and making detailed cuts for specific designs. Fabricators use tools like grinders, routers, and chisels to shape the stone.

The shaping process may include creating curved edges, cut-outs, or grooves. This step is important for achieving the desired look and functionality of the finished product.

Polishing for a Smooth Finish

Polishing involves smoothing the stone’s surface to enhance its appearance and feel. Fabricators use polishing pads with different levels of grit to gradually smooth the stone.

Starting with rough grit and moving to finer grit, the stone becomes glossy and smooth. Polishing not only improves the look but also protects the stone from stains and scratches.

Installing the Finished Stone

Once the stone is cut, shaped, and polished, it is ready for installation. Fabricators transport the finished product to the site, where it is carefully installed.

Proper installation is key to ensuring the stone is secure and fits perfectly in its intended space. Installation may involve sealing the stone to protect it from moisture and stains.

Different Uses of Fabricated Stone

In homes, fabricated stone is popular for kitchen countertops, bathroom vanities, and flooring. In commercial spaces, it is used for reception desks, wall cladding, and staircases. The versatility of stone makes it a preferred material in many industries, including construction, interior design, and architecture.

The Art and Skill of Stone Fabrication

In the end, stone fabrication transforms raw stone into beautiful, functional products that enhance various spaces. While the process can be challenging, the results are worth the effort. Whether for countertops, floors, or decorative pieces, this adds value and style to any project.